DsPIC30F 5011 Development Board

Jump to navigation

Jump to search

Contents

- 1 Introduction

- 2 Programming Methods

- 3 Circuit Design and PCB

- 4 Development Environment

- 5 Software Architecture

- 6 Programming Tips

- 7 Bootloader Development

- 8 USB-RS232 Bridge

- 9 Programming the Device

- 10 FreeRTOS and POSIX-compliant API

- 11 Remote Access

- 12 To Do List

Introduction

Features of dsPIC30F5011

- 2.5 to 5V

- Up to 30MIPs

- High current/sink source I/O pins: 25mA

- DSP Instruction Set

- Dual programming techniques: ICSP and RTSP

- UART: up to 2 modules

- I2C: up to 1Mbps

- 10-bit A/D, 1.1 Msps

- 12-bit A/D, 200 ksps

- 44K flash (66Kb), 4Kb RAM, 1Kb EEPROM

- No DAC

Web Page

Forum

- Microchip: Official forum by Microchip

- MPLAB ICD 2: Subforum on ICD 2 programmer

- MPLAB IDE: Subforum on IDE

- MPLAB C30 Compiler, ASM30, Link30 forum: Subforum on C compiler. Refer to MPLAB C30 C Compiler User's Guide Chapter 3

- dsPIC30F Topics: Subformum on dsPIC30F

- GNUPIC: Discussion on PIC in Linux Systems

- HI-TECH Software Forum: Discussion on dsPICC, a C compiler developed by HI-TECH

- PICList: Discussion on older PIC systems (not dsPIC)

- PicKit: Discussion on PICkit/PICkit 2 programmers

- FreeRTOS Real Time Kernel: Open Discussion and Support on FreeRTOS

References

- dsPIC30F

- Family Overview

- Family Reference Manual: Contains detailed descriptions on dsPIC30F register definitions and example codes

- 5011 Data Sheet **Flash Programming Specification

- Programmer Reference Manual

- ICD2 Programmer

- MPLAB

- C30 Compiler

- MPLAB C30 C Compiler User's Guide: Contains commands for using pic30-elf-gcc

- 16-bit Language Tools Libraries: Contains summaries and examples of using DSP libraries, standard C libraries and device libraries

- MPLAB ASM30, MPLAB LINK30 and Utilities User's Guide

- dsPIC30F Language Tools Quick Reference Card

Programming Methods

- There are 2 programming methods: In-Circuit Serial Programming (ICSP) and Run-Time Self-Programming (RTSP)

- ICSP allows the devices to be programmed after being placed in a circuit board.

- RTSP allows the devices to be programmed when an embedded program is already in operation.

ICSP: External Programmer (ICD2)

- Two types of ICSP are available: ICSP and Enhanced ICSP. Both of them require setting MCLR# to VIHH (9V – 13.25V).

- Standard ICSP

- Use external programmer (e.g. MPLAB® ICD 2, MPLAB® PM3 or PRO MATE® II) only.

- Required low-level programming to erase, program and verify the chip.

- Slower, because codes are serially executed.

- Program memory can be erased using Normal-Voltage (4.5 – 5.5V) or Low-Voltage (2.5V – 4.5V).

- Enhanced ICSP

- Use external programmer and Programming Executive (PE).

- PE is stored in the on-chip memory.

- PE allows faster programming.

- PE can be downloaded to the chip by external programmer using the standard ICSP method.

- PE contains a small command set to erase, program and verify the chip, avoiding the need of low-level programming.

Hardware Interface

| Pin Label | Function | Pin Number |

|---|---|---|

| MCLR# | Programming Enable | 7 |

| VDD | Power Supply | 10, 26, 38, 57 |

| VSS | Ground | 9, 25, 41, 56 |

| PGC | Serial Clock | 17 |

| PGD | Serial Data | 18 |

| Product Name | Interface with PC | Interface with Device | Price (US) | Postage (US) | Total (US) |

|---|---|---|---|---|---|

| MPLAB® ICD 2 | USB or RS232 | 6-PIN RJ-12 connector | $159.99 | - | - |

| Full Speed USB Microchip ICD2 Debugger and Programmer |

USB | 6-PIN ICSP connector 6-PIN RJ-12 connector |

$72.00 | $12.00 | $84.00 |

| Mini Microchip Compatible ICD2 Debugger and Programmer |

RS232 | 6-PIN ICSP connector 6-PIN RJ-12 connector |

$45.00 | $10.00 | $55.00 |

| ICDX30 | RS232 | 6-pin RJ-11 | $51.00 | $47.46 | $98.46 |

| Clone Microchip ICD2 | USB | 6-pin flat cables | $30.00 | $12.00 | $42.00 |

| Source | Schematic | PIC16F877A Bootloader |

|---|---|---|

| Patrick Touzet | Yes | HEX |

| Nebadje | Yes | Zip |

Software Interface

- The program can be written and compiled in an Integrated Development Environment (IDE) using either Assembly or C. The complied codes are then loaded to the device through the external programmer.

| Product Name | Features | OS | Price (US$) |

|---|---|---|---|

| MPLAB® IDE | Assembler Only | Windows | Free |

| MPLAB® C30 | Assembler and C-Compiler | Windows | $895.00 (Free student version1) |

| Piklab 0.12.0 | Assembler and C-Compiler | Linux | Free2 |

- Full-featured for the first 60 days. After 60 days only optimization level 1 can be enabled in the compiler. The compiler will continue to function after 60 days, but code size may increase.

- The current version supports external programmer ICD 2, but not yet tested.

RTSP: COM Port (Bootloader)

- RTSP works in normal voltage (^MCLR no need to raise to VIHH).

- No literature has mentioned the incorporation of Programming Executive (PE). Presumably, since Enhanced ICSP needs to set MCLR# to VIHH, RTSP cannot use PE.

- Refer to bootloader section.

Circuit Design and PCB

IC Requirements

| Part No. | Description | Min Temp | Max Temp | Min Volt | Max Volt | Typ Cur | Max Cur |

|---|---|---|---|---|---|---|---|

| dsPIC30F5011-30I/PT | uP | -40oC | 85oC | 2.5V [1] | 5.5V | 250mA | |

| MAX3232ESE | RS232 driver | -40oC | 85oC | 3.0V | 5.5V | 0.3mA | 1.0mA |

| ADM483E ANZ | RS485 driver | -40oC | 85oC | 4.5V | 5.5V | 0.036mA | |

| DAC6574DGS | 10-bit Quad-DAC I2C | -40oC | 105oC | 2.7V | 5.5V | 0.6mA | 0.9mA |

| 74HC14D | Quad-Schmitt Trigger | -40oC | 125oC | 2.0V | 6.0V | 50mA | |

| Overall | -40oC | 85oC | 4.5V | 5.5V | <310mA [2] |

- Minimum voltage measured is 3.3V (with 2 LEDs blinking) running at 30MHz.

- Measured current at 5V is 180mA (with 2 LEDs blinking only)

Module Board

- Functions

- Primary communication with other module boards via RS232 over short distance.

- Secondary communication with benchtop via RS458 over longer distance.

- Digital control I/O for 1 laser (e.g. on/off, detect temp overheat, current alarm)

- Analog input for data acquisation on power, current and temperature

- Analog output for power and current control

| Digital Input | Digital Output | Analog Input | Analog Output |

|---|---|---|---|

| 1. ICSP | 1. LED 2. Bi-color LED 3. RS232 4. RS458 5. Case temp overheat 6. Laser on/off 1,2 7. Interlock 8. Digital ctrl 9. Current 0,1 alarm |

1. Case temp 2. pow 0,1 3. cur0 4. temp0 |

1. 10-bit DAC |

Benchtop

- Functions

- Primary communciation with module boards via RS485

- Secondary communication with other benchtops via RS232

- Digital I/O control for 2 lasers

- Analog inputs on power, current and temperature

- Analog outputs for power and current control

- LCD display and rotary key for user input

| Digital Input | Digital Output | Analog Input | Analog Output |

|---|---|---|---|

| 1. ICSP 2. Rotary Key 3. Push Buttons |

1. LED 2. RS232 3. RS458 4.LCD display 5. Buzzer 6. Digital Ctrl 0,1 |

1. Case temp 2. CurrentDetect 0,1 3. PowerDetect 0,1,2,3 4. TempDetect |

1. 10-bit DAC (PowerCurrentCtrl 0,1) |

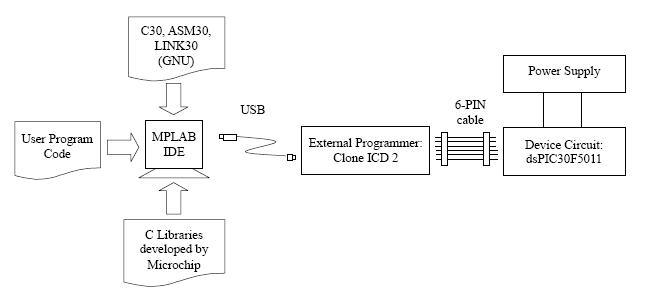

Development Environment

Windows

- C-Compiler, Assembler and Linker are under GNU license.

- MPLAB C30 C Compiler (*.c -> *.s)

- MPLAB ASM30 Assembler (*.s -> *.o)

- MPLAB LINK30 Linker (*.o -> *.bin)

- PA optimizer, simulator, runtime libraries, header files, include files, and linker scripts are not covered by GNU. Reference is here.

- Microchip has integrated ASM30, LINK30, assembly header files, linker scripts in MPLAB IDE, which is free for download.

- MPLAB C30 costs US$895. A 60-day free student version is also available. After 60-days, the optimizer is automatically disabled, while other tools can still function properly. Refer to Table 2.4.

- C-libraries contained in C30 includes (Refer to 16-Bit Language Tools Libraries from Microchip).

| Library | Directory (\\Microchip\MPLAB C30) |

Major functions |

|---|---|---|

| DSP Library (e.g. libdsp-coff.a) |

\lib \src\dsp \support\h |

Vector, Matrix, Filter, etc. |

| 16-Bit Peripheral Libraries (e.g. libp30F5011-coff.a) |

\lib \src\peripheral \support\h |

ADC12, IOPort, UART, I2C, etc. |

| Standard C Libraries (e.g. libc-coff.a, libm-coff.a, libpic-coff.a) |

\lib \src\libm \include |

stdio.h, time.h, float.h, math.h, |

| MPLAB C30 Built-in Functions | none | _buildin_addab, _buildin_add, _buildinmpy, etc |

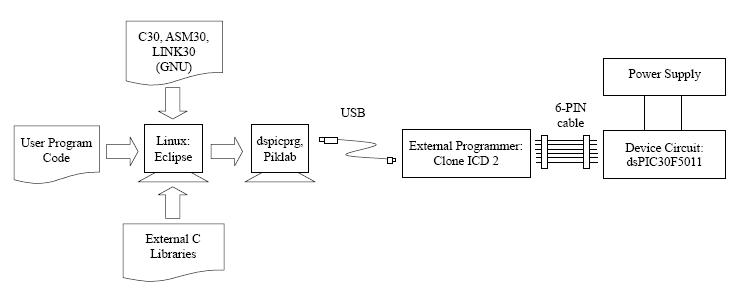

Linux

- C Compiler, Assembler and Linker are under GNU license.

- The code can be downloaded from Microchip at here.

- Current MPLAB ASM30 Assembler: v2.04

- Current MPLAB C30 Compiler: v2.04

- John Steele Scott has made templates that can be readily used by Debian-based systems. Someone at http://noel.feld.cvut.cz/dspic/ has done the necessary conversion to *.deb already.

- Download pic30-1.32-debian.tar.bz2 for Template v1.32. (For v2.01, please goto pic30-debian-2.01.tar.bz2).

- Download pic30-binutils_1.32-1_i386.deb for the assember.

- Download pic30-gcc_1.32-1_i386.deb for the compiler.

- Important Note: Only the compiler is free. The header files and library is owned by Microchip.

- Thomas Sailer suggested to download the Student version of C30 compiler and then build the libraries without source code. A package template for Fedora system is available here.

- Instructions for filling the upstream direction is available here.

- Alteratively, Stephan Walter has started a project to develop C Runtime Library for dsPIC.

- Current libraries in version 0.1.1 include: assert.h, cdefs.h, ctype.h, errno.h, inttypes.h, stdint.h, stdio.h, stdlib.h, string.h

- Burning Program Codes to Target Board

- Use 'dspicprg and dspicdmp' utilities developed by Homer Reid to burn hex code (*.hex) to devices. See Reference here. Through serial port only?

- Use Piklab IDE. Details on file format not known.

- Use MPLAB IDE to burn hex code (*.hex) to devices.

Code Optimization

- Code Optimization under GNU license supports O0 and O1 only.

- MPLAB C-Compiler supports O0, O1, O2, Os and O3. The Student version will disable O2, Os, and O3 after 60 days.

- Below is a comparsion between different optimization levels for the project including drivers for 2 projects.

| Optimization | Description | Project 1 Code Size (byte) |

Project 1 Data Usage (byte) |

Project 2 Code Size (byte) |

Project 2 Data Usage (byte) |

|---|---|---|---|---|---|

| O0 | No optimization Fastest Compilation |

6222 (9%) | 178 (4%) | 26,037 (38%) | 710 (17%) |

| O1 | Optimize Tries to reduce code size and execution time. |

4473 (6%) | 178 (4%) | 22,290 (32%) | 710 (17%) |

| O2 | Optimize even more Performs nearly all supported optimizations that do not involve a space-speed trade-off. Increases both compilation time and the performance of the generated code. |

4422 (6%) | 178 (4%) | 21,993 (32%) | 710 (17%) |

| O3 | Optimize yet more. O3 turns on all optimizations specified by O2 and also turns on the inline-functions option. |

4485 (6%) | 178 (4%) | 22,176 (32%) | 710 (17%) |

| Os | Optimize for size. Os enables all O2 optimizations that do not typically increase code size. It also performs further optimizations designed to reduce code size. |

4356 (6%) | 178 (4%) | 21,885 (32%) | 710 (17%) |

Software Architecture

+----------+-----------+---------+---------+ | local | remote | | | +----------+-----------+ host | UI | | data access | channel | | | (DI,DO,AI,AO) | | | +----------------------+---------+---------+ | Application | | | +------------------------------------------+ | Applications Model | | +--------------+-----------+ | | | GUI | CLib | | | | +------+-----------+-------+ | | | Operating System | +-------+-------+--------------------------+ | Drivers | +------------------------------------------+ | Hardware | +------------------------------------------+

- Currently, operating system is based on linlike8. The possibility of using other OS (e.g. FreeRTOS) will be explored later.

- Software Drivers are to be developed to allow users at Application Level to use the hardware (e.g. ADC, DAC, UART, EEPROM) through the OS.

- The interface between the drivers and the OS should be compliant with POSIX standard for Linux (e.g. open(), write(), read(), ioctl() etc).

Programming Tips

Memory Map for 5011

| Type | Start Address | End Address | Size |

|---|---|---|---|

| Flash | 0x000000 | 0x00AFFF | 44K[1] |

| +--Flash: Reset Vector | 0x000000 | 0x000003 | 4 |

| +--Flash: Interrupt Vector Table | 0x000004 | 0x00007F | 124 |

| +--Flash: Alternate Vector Table | 0x000084 | 0x0000FF | 124 |

| +--Flash: User Program | 0x000100 | 0x00AFFF | 43.7K |

| EEPROM | 0x7FFC00 | 0x7FFFFF | 1K[2] |

| Programming Executive | 0x800000 | 0x8005BF | 1472 |

| Unit ID | 0x8005C0 | 0x8005FF | 64 |

| Config Registers | 0xF80000 | 0xF8000F | 16 |

| Device ID | 0xFF0000 | 0xFF0003 | 4 |

[1] Each address is 16-bit wide. Every two addresses correspond to a 24-bit instruction. Each even address contains 2 valid bytes; each odd address contains 1 valid byte plus 1 phathom byte.

[2] Each address is 8-bit wide.

Data Location

| Type | Description | Example |

|---|---|---|

| _XBSS(N) [1] | RAM Data in X-memory, aligned at N, no initilization | int _XBSS(32) xbuf[16]; |

| _XDATA(N) [1] | RAM Data in X-memory, aligned at N, with initilization | int _XDATA(32) xbuf[] = {1, 2, 3, 4, 5}; |

| _YBSS(N) [1] | RAM Data in Y-memory, aligned at N, no initilization | int _YBSS(32) ybuf[16]; |

| _YDATA(N) [1] | RAM Data in Y-memory, aligned at N, with initilization | int _YDATA(32) ybuf[16] = {1, 2, 3, 4, 5}; |

| __attribute__((space(const))) | Flash ROM data, constant, accessed by normal C statements, but 32K max. |

int i __attribute__((space(const))) = 10; |

| __attribute__((space(prog))) | Flash ROM data, read/write by program space visibility window (psv) |

int i __attribute__((space(prog))); |

| __attribute__((space(auto_psv))) | Flash ROM data, read by normal C statements, write by accessing psv |

int i __attribute__((space(auto_psv))); |

| __attribute__((space(psv))) | Flash ROM data, read/write by (psv) | int i __attribute__((space(psv))); |

| _EEDATA(N) [1] | ROM Data in EEPROM, aligned at N, read/write with psv | int _EEDATA(2) table[]={0, 1, 2, 3, 5, 8}; |

| _PERSISTENT | RAM Data, data remain after reset | int _PERSISTENT var1, var2; |

| _NEAR | RAM Data at near section | int _NEAR var1, var2; |

| _ISR | Interrupt service rountine | void _ISR _INT0Interrupt(void); |

| _ISRFAST | Fast interrupt service rountine | void _ISRFAST _T0Interrupt(void); |

- N must be a power of two, with a minimum value of 2.

Configuration Bits

- System clock source can be provided by:

- Primary oscillator (OSC1, OSC2)

- Secondary oscillator (SOSCO and SOSCI) with 32kHz crystal

- Internal Fast RC (FRC) oscillator at 7.37MHz (7372800Hz)

- Low-Power RC (LPRC) oscillator (Watchdog Timer) at 512 kHz.

- These clock sources can be incorporated with interal Phase-locked-loop (PLL) x4, x8 or x16 to yield the osciallator frequrence FOSC

- The system clock is divided by 4 to yield the internal instruction cycle clock, FCY=FOSC/4

- FRC with PLLx16 is used to achieve FCY=29.49MHz (29491200Hz or 30MIPS)

//The code (MACRO) below is to be placed at the top of program (before main)

_FOSC(CSW_FSCM_OFF & FRC_PLL16);

_FWDT(WDT_OFF); //Turn off Watchdog Timer

_FBORPOR(PBOR_ON & BORV_27 & MCLR_DIS & PWRT_16);

_FGS(CODE_PROT_OFF); //Disable Code Protection

Timer

- Each timer is 16-bit (i.e. counting from 0 to 65535).

- Timer 2 and 3 can be incorporated together to form a 32-bit timer.

- Prescale is the ratio between timer counts and system clock counts. Prescales of 1:1, 1:8, 1:64 and 1:256 are available.

- Timers may be used to implement free time clock or mesaure time.

Free Time Clock

- Let required time for ticking be PERIOD.

- Number of instruction cycles during PERIOD = PERIOD*FCY cycles

- Using a prescale of 1:x, the timer period count register = # of cycles/x

- e.g. PERIOD = 10ms; # of cycles = 10ms*30MHz = 300000 cylces; Using 1:64 Prescale, register setting = 300000/64 = 4688

void time_init(void){

TMR1 = 0; // Clear register

PR1 = 4688; // Set period

//============================================================

_T1IF = 0; // Clear interrupt flag

_T1IE = 1; // Enable interrupts

//============================================================

T1CONbits.TCS = 0; // Use internal clock source

T1CONbits.TCKPS = 2; // Prescale Select 1:64

T1CONbits.TON = 1; // Start the timer

}

//********************************************************************

void _ISRFAST _T1Interrupt(void){

_T1IF = 0; // Clear interrupt flag

//Place user code here

}

Time Measurement

- To measure the time taken for action(), use the code below:

unsigned int measure_time(void){

PR3 = 0xFFFF; // Set counter to maximum

_T3IF = 0; // Clear interrupt flag

_T3IE = 0; // Disable interrupt

T3CONbits.TON = 1; // Start the timer, TMR3 count up

TMR3 = 0; //Clear TMR3 to start count up

//====================================================

//Add code here to wait for something to happen

action();

//====================================================

T3CONbits.TON = 0; //Stop the timer

//====================================================

return (unsigned int) TMR3/FCY; //TMR/FCY yields the actual time

}

Interrupt

- Registers are involved in Interrupts includes:

- Interrupt Flag Status (IFS0-IFS2) registers

- Interrupt Enable Control (IEC0-IEC2) registers

- Interrupt Priority Control (IPC0-IPC10) registers

- Interrupt Priority Level (IPL) register

- Global Interrupt Control (INTCON1, INTCON2) registers

- Interrupt vector (INTTREG) register

- User may assign priority level 0-7 to a specific interrupt using IPC. Setting priority to 0 disable a specific interrupt. Level 7 interrupt has the highest priority.

- Current priority level is stored in IPL. Setting IPL to 7 disables all interrupts (except traps). The following MACROs are defined in <p30f5011.h>:

- SET_CPU_IPL(ipl): Set IPL to ipl

- SET_AND_SAVE_CPU_IPL(save_to, ipl): Store the current IPL to save_to and then set to ipl

- RESTORE_CPU_IPL(saved_to): Restore the previously saved ipl

- sti() and cli() are defined to enable and disable global interrupts for time critical functions:

extern int SAVE_IPL;

#define sti() RESTORE_CPU_IPL(SAVE_IPL)

#define cli() SET_AND_SAVE_CPU_IPL(SAVE_IPL, 7)

//============================================================

char adc_ioctl(unsigned char request, unsigned char* argp){

//...

cli(); //Disable global interrupt

for(;ch<=argp[0];ch++)

adc_add_ch(argp[ch]); //Add adc channels

sti(); //Enable global interrupt

//...

return 0;

}

UART

- 5011 provides two UART channels UxART, for x=1, 2.

- UxMODE, UxSTA, UxBRG are registers used to set the mode, indicate the status, and set the baud rate respectively.

- For UART communications compatiable with RS232 standard, an external driver (e.g. MAX3232ESE) is needed.

- For UART communications compatiable with RS485 standard, an external driver (e.g. DS3695N) is needed.

Auto baud rate detection

- The method is provided by ingenia bootloader.

- The PC sends a ASCII character 'U' (0x55) to the target board.

- On the first rising edge of the start bit, the target board starts the timer.

- At the fifth rising edge, the timer is stopped, let the count number be t_count.

- The measured period corresponds to 8 bits transmitted at a baud rate uxbrg.

_ _ _ _ _ _ _|S|_|1|_|1|_|1|_|1|_|S|_ (S = Start Bit) <---------------> Measured Time

- The relationship between uxbrg and TMR is

Measured Time (in seconds) = t_count/Fcy

uxbrg = 1/(Measured Time/8)

= 8*Fcy/t_count

- Since UxBRG is computed by:

UxBRG = (Fcy/(16*Baudrate)) -1

= (Fcy/(16*8*Fcy/t_count)) -1

= t_count/128 -1

- The following is the code for auto baud rate detection for U2ART:

unsigned int uart2_autobaud(void){

U2MODEbits.ABAUD = 1; //Enable Autobaud detect from U2RX (from IC2 if 0)

U2MODEbits.UARTEN = 1; //U2ART enable

//Timer 3 Config==========================================================

PR3 = 0xFFFF; // Set counter to maximum

_T3IF = 0; // Clear interrupt flag

_T3IE = 0; // Disable interrupt

T3CONbits.TON = 1; // Start the timer, TMR3 count up

//Input Capture Config====================================================

IC2CONbits.ICM = 3; //Detect rising

_IC2IF = 0; //Clear interrupt flag

_IC2IE = 0; //Disable interrupt

//Start Auto baud detection===============================================

unsigned int i=0;

cli(); //Disable Global Interrupt

while(!_IC2IF); //1st rising edge detected

TMR3 = 0; //Clear TMR3 to start count up

_IC2IF = 0; //Clear interrupt flag

while(!_IC2IF); //2nd rising edge detected

_IC2IF = 0; //Clear interrupt flag

while(!_IC2IF); //3rd rising edge detected

_IC2IF = 0; //Clear interrupt flag

while(!_IC2IF); //4th rising edge detected

_IC2IF = 0; //Clear interrupt flag

while(!_IC2IF); //5th rising edge detected

_IC2IF = 0; //Clear interrupt flag

T3CONbits.TON = 0; //Stop the timer

sti(); //Enable Global Interrupt

//Compute value for BRG register==========================================

unsigned int time;

time = ((TMR3+0x40)>>7)-1; //+0x40 for rounding

//========================================================================

return time;

}

- For 30MIP, tested speeds of transmission include 9600bps, 19200bps, 28800bps, 38400bps and 57600bps.

Initialize UART

void uart2_init(void){

//=================================================================

// Configure Baud rate

// +-- Default Baud rate = 19.2 kbps

// +-- U2BRG = 30e6 / (16 * 19200) - 1 = 97

unsigned int u2brg = 97;

#if(AUTO_BAUD_DECT>0)

u2brg = uart2_autobaud();

#endif

U2BRG = u2brg;

//=================================================================

// Disable U2ART

U2MODEbits.UARTEN = 0; //Disable U2ART module

//=================================================================

// Configure Interrupt Priority

_U2RXIF = 0; //Clear Rx interrupt flags

_U2TXIF = 0; //Clear Tx interrupt flags

_U2RXIE = 1; //Receive interrupt: 0 disable, 1 enable

_U2TXIE = 1; //Transmit interrupt: 0 disable, 1 enable

//=================================================================

// Configure Mode

// +--Default: 8N1, no loopback, no wake in sleep mode, continue in idle mode

// +--Diable autobaud detect

// +--Enable U2ART module

U2MODEbits.ABAUD = 0; //Disable Autobaud detect from U2RX

U2MODEbits.UARTEN = 1; //U2ART enable

//=================================================================

// Configure Status

// +--Default: TxInt when a char is transmitted, no break char

// +--Default: RxInt when a char is received, no address detect, clear overflow

// +--Enable Transmit

U2STAbits.UTXEN = 1; //Tx enable

}

Sending and Receiving Data

void _ISR _U2TXInterrupt(void){

_U2TXIF = 0; //Clear Interrupt Flag

if(tx_data_ready())

U2TXREG = tx_buf[POS]; //send next byte...

}

void _ISR _U2RXInterrupt(void){

_U2RXIF = 0; //Clear the flag

if ( U2STAbits.URXDA ){

rx_buf[POS] = (unsigned char) U2RXREG; //Read the data from buffer

}

}

I2C

- Two lines are devoted for the serial communication. SCL for clock, SDA for data.

- Standard communication speed includes

- Standard speed mode: 100kHz

- Fast speed mode: 400kHz

- High speed mode: 3.4MHz

- dsPIC30f5011 supports standard and fast speed modes. The maximum speed attainable is 1MHz.

- Pull-up resistors are required for both SCL and SDA. Minimum pull-up resistance is given by:

Pull-up resistor (min) = (Vdd-0.4)/0.003 ...... [See section 21.8 in Family reference manual]

- 2.2Kohm is typical for standard speed mode.

- After initiating a start/stop/restart bit, add a small delay (e.g. no operation) before polling the corresponding control bit (hardware controlled). For example:

StartI2C();

Nop(); //A small delay for hardware to respond

while(I2CCONbits.SEN); //Wait till Start sequence is completed

- After sending a byte and receiving an acknowledgement from the slave device, ensure to change to idle state. For example:

MasterWriteI2C(0x55);

while(I2CSTATbits.TBF); //Wait for transmit buffer to empty

while(I2CSTATbits.ACKSTAT); //Wait for slave acknowledgement

IdleI2C();

ADC

- 12-bit ADC: (Max 16 Channels)

- Allow a maximum of 2 sets of analog input multiplexer configurations, MUX A and MUX B (Normally use one only).

- A maximum of 200kps of sampling rate when using auto sampling mode.

Configuration

- Interrupt: Clear ADC interrupt flag and enable ADC interrupt. The ADC module will be set to interrupt when the specified channels are updated.

_ADIF = 0; //clear ADC interrupt flag _ADIE = 1; //enable adc interrupt

- I/O: Set the corresponding TRISBX bits (digit i/o config) to input (i.e. = 1), and set corresponding bits in ADPCFG (analog config) to zero.

_TRISB2 = 1; //Set AN2 [Case Temp] as analog input _TRISB8 = 1; //Set AN8 [Power detect 0] as analog input _TRISB9 = 1; //Set AN9 [Power detect 1] as analog input _TRISB10 = 1; //Set AN10 [Current detect 0] as analog input _TRISB11 = 1; //Set AN11 [Temp detect 0] as analog input ADPCFG = 0xF0FB; //0 => Analog, 1 => Digital

- Scanning Mode: Scan mode is used. In this mode, the Sample and Hold (S/H) is switched between the channels specified by ADCSSL (Scan select register).

ADCSSL = 0x0F04; //0 => Skip, 1 => Scan

- Reference Voltage for S/H: Only MUX A is used. By default, the negative reference voltage of the S/H is connected to VREF-.

ADCHSbits.CH0NA = 0;

- Sampling Rate: TAD refers to the time unit for the ADC clock. To configure the ADC module at 200kbps, the minimum sampling time of 1TAD = 334ns is required. ADCS<5:0> in ADCON3 register is used to set the time, which is given by:

ADCS<5:0> = 2(TAD/TCY)-1

= 2(334e-9/33.34e-9)-1

= 19

ADCON3bits.SAMC = 1; //1TAD for sampling time

ADCON3bits.ADRC = 1; //Use internal ADC clock

ADCON3bits.ADCS = 19; //Set TAD = 334ns

- Settings for ADC Operation: For 200kbps operation, the voltage references for the ADC voltage are connected to VREF+ and VREF-. Scan input is enabled, and the module will generate an interrupt when all selected channels have been scanned.

ADCON2bits.VCFG = 3; //External Vref+, Vref-

ADCON2bits.CSCNA = 1; //Scan input

ADCON2bits.SMPI = 4; //take 5 samples (one sample per channel) per interrupt

- More Settings for ADC Operation: Turn on the module, select the data output format as unsigned integer, and allow auto setting of SAMP bit (auto sampling).

ADCON1bits.ADON = 1; //Turn on module

ADCON1bits.FORM = 0; //[2 fractional]; [3 siged fractional]

ADCON1bits.SSRC = 7; //auto covert, using internal clock source

ADCON1bits.ASAM = 1; //auto setting of SAMP bit

Storing ADC Data

- 16 registers (ADCBUF0 -ADCBUF15) are dedicated to store the ADC data between interrupts. However, the data in ADCBUFx does not necessarily correspond to the data taken for channel x. Since the lowest register will always be filled first, when some of the channels are not scanned (i.e. skipped), care must be taken. The following code checks the ADCSSL register for the current scanning channels and moves the data to the corresponding position in *adc_buf.

void _ISR _ADCInterrupt(void){

_ADIF = 0; //Clear adc interrupt

//==========================================================

unsigned char channel = 0;

unsigned char buffer = 0;

for (; channel<ADC_MAX_CH; channel++){

if(adc_ch_updated(channel)){ //Check if channel has updated

adc_buf[channel] = ADC16Ptr[buffer]; //Copy data to adc_buf

buffer++;

}

}

}

unsigned char adc_ch_updated(unsigned char ch){

unsigned int mask;

mask = 0x0001 << ch;

if(ADCSSL & mask)

return 1;

return 0;

}

Adding and Removing Channels

- Channels may be added or removed by changing _TRISBX, ADPCFG, ADCSSL and ADCON2bits.SMPI.

void adc_add_ch(unsigned char ch){

//Enable i/o pin as input===========================================

switch(ch){

case 0: _TRISB0 = 1; break;

case 1: _TRISB1 = 1; break;

case 2: _TRISB2 = 1; break;

case 3: _TRISB3 = 1; break;

case 4: _TRISB4 = 1; break;

case 5: _TRISB5 = 1; break;

case 6: _TRISB6 = 1; break;

case 7: _TRISB7 = 1; break;

case 8: _TRISB8 = 1; break;

case 9: _TRISB9 = 1; break;

case 10: _TRISB10 = 1; break;

case 11: _TRISB11 = 1; break;

case 12: _TRISB12 = 1; break;

case 13: _TRISB13 = 1; break;

case 14: _TRISB14 = 1; break;

default: _TRISB15 = 1;

}

unsigned int mask;

mask = 0x0001 << ch;

ADCSSL = ADCSSL | mask;

ADPCFG = ~ADCSSL;

ADCON2bits.SMPI++; //take one more sample per interrupt

}

void adc_rm_ch(unsigned char ch){

unsigned int mask;

mask = 0x0001 << ch;

ADPCFG = ADPCFG | mask;

ADCSSL = ~ADPCFG;

ADCON2bits.SMPI--; //take one less sample per interrupt

}

EEPROM

- 5011 has 1024 bytes of EEPROM, readable and writable under normal voltage (5V).

- To use, declare:

unsigned char _EEDATA(2) eeData[1024]={ 0x00, 0x00, 0x00, 0x00, .... }

unsigned int byte_pointer = 0;

Seek

- This function moves the pointer to the desired position before a reading/writing operation is performed.

int eeprom_lseek(int offset, unsigned char whence){

byte_pointer = offset;

return byte_pointer;

}

Read

- This function read count bytes from the eeprom.

int eeprom_read(unsigned char* buf, int count){

int i=0;

for(; i<count && byte_pointer < 1024; i++){

readEEByte( __builtin_tblpage(eeData),

__builtin_tbloffset(eeData) + byte_pointer,

&buf[i]);

byte_pointer++; //Update global pointer

}

return i; //read i bytes successful

}

- readEEByte() is implemented in assembly code as follows:

.global _readEEByte

_readEEByte:

push TBLPAG ;w0 = base of eeData

mov w0, TBLPAG ;w1 = offset for eeData in byte

tblrdl.b [w1], [w2] ;w2 = pointer to user buffer

pop TBLPAG

return

Write

- This function write count bytes to eeprom.

int eeprom_write(unsigned char* buf, int count){

char isOddAddr = byte_pointer%2; //current address is odd

char isOddByte = count%2; //number of bytes to write is odd

//=================================================================

unsigned int word_offset = byte_pointer>>1; //div by 2 and round down

int max_write;

max_write = (isOddAddr == 0 && isOddByte == 0) ? (count>>1) : (count>>1)+1;

//=================================================================

unsigned int word_data; //Store word to be written

int byte_wr = 0; //number of bytes written, i.e buffer pointer

int i = 0;

//=================================================================

for(; i<max_write && word_offset<512; i++, word_offset++){

if(i==0 && isOddAddr){

//First byte not used

//============================================save first byte

readEEByte( __builtin_tblpage(eeData),

__builtin_tbloffset(eeData) + byte_pointer - 1,

&word_data);

//===========================================================

word_data = ((unsigned int)buf[0] << 8) + (0xFF & word_data);

byte_wr++; //Update buffer pointer

byte_pointer++; //Update global pointer

} else if(i==max_write-1 && ((isOddAddr && sOddByte==0)||(isOddAddr==0 && isOddByte))){

//Last byte not used

//=============================================save last byte

readEEByte( __builtin_tblpage(eeData),

__builtin_tbloffset(eeData) + byte_pointer + 1,

&word_data);

//============================================================

word_data = (word_data << 8) + buf[byte_wr];

byte_wr++; //Update buffer pointer

byte_pointer++; //Update global pointer

} else{

//Both bytes valid

word_data = ((unsigned int)buf[byte_wr+1] << 8) + buf[byte_wr];

byte_wr+=2; //Update buffer pointer

byte_pointer+=2; //Update global pointer

}

//==================================================================

eraseEEWord( __builtin_tblpage(eeData),

__builtin_tbloffset(eeData) + 2*word_offset);

writeEEWord( __builtin_tblpage(eeData),

__builtin_tbloffset(eeData) + 2*word_offset,

&word_data);

//==================================================================

}

return byte_wr; //No. of byte written

}

- eraseEEWord and writeEEWord are implemented in assembly.

.global _eraseEEWord

_eraseEEWord:

push TBLPAG

mov w0, NVMADRU ;w0 = base of eeData

mov w1, NVMADR ;w1 = offset for eeData in word

mov #0x4044, w0

mov w0, NVMCON ;Set to erase operation

push SR ;Disable global interrupts

mov #0x00E0, w0

ior SR

mov #0x55, w0 ;Write the KEY sequence

mov w0, NVMKEY

mov #0xAA, w0

mov w0, NVMKEY

bset NVMCON, #15 ;Start the erase cycle, bit 15 = WR

nop

nop

L1: btsc NVMCON, #15 ;while(NVMCONbits.WR)

bra L1

clr w0

pop SR ;Enable global interrupts

pop TBLPAG

return

.global _writeEEWord

_writeEEWord:

push TBLPAG ;w0 = base of eeData

mov w0, TBLPAG ;w1 = offset for eeData in byte

tblwtl [w2], [w1] ;w2 = pointer to user buffer

mov #0x4004, w0 ;Set to write operation

MOV w0, NVMCON

push SR ;Disable global interrupts

mov #0x00E0, w0

ior SR

mov #0x55, w0 ;Write the KEY sequence

mov w0, NVMKEY

mov #0xAA, w0

mov w0, NVMKEY

bset NVMCON, #15 ;Start the erase cycle, bit 15 = WR

nop

nop

L2: btsc NVMCON, #15 ;while(NVMCONbits.WR)

bra L2

clr w0

pop SR ;Enable global interrupts

pop TBLPAG

return

Simple PWM (Output Compare Module)

- The PWM module consists of 8 channels using the output compare module of dsPic.

- These channels are locate at pin 46 (OC1), 49 (OC2), 50 (OC3), 51 (OC4), 52 (OC5), 53 (OC6), 54 (OC7), 55 (OC8). These pins are shared with port D.

- The range of PWM freqeuencies obtainable is 2Hz to 15MHz (See Figure 6.3). Suggested range of operation is 2Hz to 120kHz. The relationship between resolution r and PWM frequency fPWM is given by:

fPWM = fCY/(Prescale*10rlog(2))

| Resolution (bit) | Prescale=1 | Prescale=8 | Prescale=64 | Prescale=256 |

|---|---|---|---|---|

| 1 | 15,000,000 | 1,875,000 | 234,375 | 58,594 |

| 2 | 7,500,000 | 937,500 | 117,188 | 29,297 |

| 3 | 3,750,000 | 468,750 | 58,594 | 14,648 |

| 4 | 1,875,000 | 234,375 | 29,297 | 7,324 |

| 5 | 937,500 | 117,188 | 14,648 | 3,662 |

| 6 | 468,750 | 58,594 | 7,324 | 1,831 |

| 7 | 234,375 | 29,297 | 3,662 | 916 |

| 8 | 117,188 | 14,648 | 1,831 | 458 |

| 9 | 58,594 | 7,324 | 916 | 229 |

| 10 | 29,297 | 3,662 | 458 | 114 |

| 11 | 14,648 | 1,831 | 229 | 57 |

| 12 | 7,324 | 916 | 114 | 29 |

| 13 | 3,662 | 458 | 57 | 14 |

| 14 | 1,831 | 229 | 29 | 7 |

| 15 | 916 | 114 | 14 | 4 |

| 16 | 458 | 57 | 7 | 2 |

open()

- A timer (either Timer 2 or 3) is needed to determine the pwm period. The following code uses timer 2 for all 8 channels.

void pwm_open(void){

OC1CON = 0; OC2CON = 0; //Disable all output compare modules

OC3CON = 0; OC4CON = 0;

OC5CON = 0; OC6CON = 0;

OC7CON = 0; OC8CON = 0;

//============================================================

TMR2 = 0; // Clear register

PR2 = 0xFFFF; // Set to Maximum

//============================================================

_T2IP = 7; // Set priority level to 7 (7 Highest)

_T2IF = 0; // Clear interrupt flag

_T2IE = 1; // Enable interrupts

//============================================================

T2CONbits.TCS = 0; // Use internal clock source

T2CONbits.TCKPS = 0; // Prescale Select 1:1

//============================================================

T2CONbits.TON = 1; // Start the timer

}

void _ISR _T2Interrupt(void){

_T2IF = 0; // Clear interrupt flag

}

ioctl()

- User should select the channel and set the pwm period using the functions below before issuing the duty cycle:

char pwm_ioctl(unsigned char request, unsigned long* argp){

unsigned int value;

unsigned char mask;

switch(request){

case PWM_SET_PERIOD:

return setPeriodNPrescale(argp[0]);

case PWM_SELECT_CH:

pwm_channel = argp[0];

mask = 0x01 << pwm_channel;

pwm_status = pwm_status | mask;

return 0;

default:

return -1;

}

}

char setPeriodNPrescale(unsigned long value_ns){

unsigned long ans;

unsigned long long numerator = (unsigned long long)value_ns*SYSTEM_FREQ_MHZ;

unsigned char index= -1;

unsigned long denominator;

//-------------------------------------------------

do{

denominator = (unsigned long)1000*pwm_prescale[++index];

ans = (unsigned long)(((long double)numerator/denominator) + 0.5) - 1; //rounding to nearest integer

} while(ans > 0x0000FFFF && index < 3);

//-------------------------------------------------

if(ans > 0x0000FFFF)

return -1;

//-------------------------------------------------

T2CONbits.TON = 0; // Turn off the timer

T2CONbits.TCKPS = index; // Change prescale factor

PR2 = (unsigned int) ans; // Set to Maximum

T2CONbits.TON = 1; // Turn on the timer

//-------------------------------------------------

return 0;

}

write()

- User can change the duty cycle using teh following functions

int pwm_write(unsigned long* buf){

if((pwm_status & (0x01 << pwm_channel)) == 0){

return -1; //Channel has not been enabled

}

switch(pwm_channel){

case 0:

OC1RS = calcDCycle(buf[0]); OC1R = OC1RS;

OC1CONbits.OCM = 6; //Simple PWM, Fault pin disabled

break;

case 1:

OC2RS = calcDCycle(buf[0]); OC2R = OC2RS;

OC2CONbits.OCM = 6; //Simple PWM, Fault pin disabled

break;

...

case 7:

OC8RS = calcDCycle(buf[0]); OC8R = OC8RS;

OC8CONbits.OCM = 6; //Simple PWM, Fault pin disabled

break;

default:

return -1;

}

return 4;

}

unsigned int calcDCycle(unsigned long value_ns){

unsigned long long numerator = (unsigned long long)value_ns*SYSTEM_FREQ_MHZ;

unsigned int index = T2CONbits.TCKPS;

unsigned long denominator = (unsigned long)1000*pwm_prescale[index];

return (unsigned int)(((long double)numerator/denominator) + 0.5) - 1; //rounding to nearest integer

}

Propagration Delay

- PWM channels sharing the same timer will have their PWM signals synchronised (i.e. the HIGH state of the duty cycle are all triggered together).

- To introduced delay to the PWM signals, the signal from selected channels may be made to pass through a series of inverters (e.g. 74HC14D). This adds propagation delay to the signal.

- However, as propagration delay of logic gates depends on applied voltage, temperature and load capacitance, the accuracy is low and performance is poor. For accurate delay, delay lines may be used, but they are expensive.

| 3.3V | 5.0V | |||||

|---|---|---|---|---|---|---|

| Number of Gates | A | B | C | A | B | C |

| 2 | 21ns (10.5) | 23ns (11.5) | 22ns (11.0) | 15ns (7.5) | 14ns (7.0) | 14ns (7.0) |

| 4 | 45ns (11.3) | 46ns (11.5) | 46ns (11.5) | 30ns (7.5) | 30ns (7.5) | 30ns (7.5) |

| 6 | 69ns (11.5) | 70ns (11.7) | 72ns (12.0) | 45ns (7.5) | 46ns (7.7) | 47ns (7.8) |

[1] Data in specification for 4.5V: Typical 15ns, Maximum 25ns

[2] Data in specification for 6.0V: Typical 12ns, Maximum 21ns

DSP Library

- Library functions in <dsp.h> include the following categories:

- Vector

- Window

- Matrix

- Filtering

- Transform

- Control

Data Types

- Signed Fractional Value (1.15 data format)

- Inputs and outputs of the dsp functions adopt 1.15 data format, which consumes 16 bits to represent values between -1 to 1-2-15 inclusive.

- Bit<15> is a signed bit, positive = 0, negative = 1.

- Bit<14:0> are the exponent bits e.

- Positive value = 1 - 2-15*(32768 - e)

- Negative value = 0 - 2-15*(32768 - e)

- 40-bit Accumulator operations (9.31 data format)

- The dsp functions use the 40 bits accumalators during arithmatic calculations.

- Bit<39:31> are signed bits, positive = 0x000, negative = 0x1FF.

- Bit<30:0> are exponent bits.

- IEEE Floating Point Values

- Fractional values can be converted to Floating point values using: fo = Fract2Float(fr); for fr = [-1, 1-2-15]

- Floating point values can be converted to Fractional values using: fr = Float2Fract(fo); or fr = Q15(fo); for fo = [-1, 1-2-15]

- Float2Fract() is same as Q15(), except having saturation control. When +ve >= 1, answer = 215-1 = 32767 (0x7FFF). When -ve < -1, answer = -215 = -32767 (0x8000)

Overflow and Saturation Traps

- To be added.

Build-in Library

- Some assembler operators can only be accessed by inline assembly code, for example,

- Manuipulation of accumulators A and B (add, sub, mul, divide, shift, clear, square)

- Bit toggling

- Access to psv (program space visiblity) page and offset

- Access to table instruction page and offset

- Built-in functions are written as C-like function calls to utilize these assembler operators.

Bootloader Development

Concepts

- Programming with ICSP is useful when the target board is produced in batch. The producer can download a program even when the chip is on the target board.

- However, ICSP requires an external programmer.

- To allow the user to change the program after production but without the need of an external programmer, bootloader becomes useful.

- Bootloader is a small program installed via ICSP. Everytime the device is reset, the bootloader is run first. The bootloader first detects the default serial channel whether the user wishes to download a new program to the device. If so, the bootloader will pause there, and wait for the user to download the hex file from the PC. The hex file is written to the device via RTSP instructions in the bootloader. If a new download is not necessary, the bootloader redirects to the previously installed user's program.

- The disadvantage of bootloaders is that they consume some of the memory of the device.

| Developer | Source | Platform | User Guide | Remarks |

|---|---|---|---|---|

| ingenia | Assembly | Windows |

| |

| Tiny | Assembly | Windows | Web |

|

| Elektronika | Hex | Windows | txt |

|

dsPicBootloader

- The bootloader developed by ingenia is open source and it has been modified (see below) to suit our development using dsPic30f5011.

- The bootloader (hereafter called dsPicBootloader) employs the following settings:

- Use U2ART channel

- Use FRC, PLL16

- For 5011, the bootloader is located between 0x00AE00 to 0x00AFFE (512bytes). Refer to C:\Program Files\Ingenia\ingeniadsPICbootloader\ibl_dspiclist.xml after installing the GUI interface.

- Changes made to assembly code includes:

1. including p30f5011.gld and p30f5011.inc

.include "p30f5011.inc"

2. changing the config code of UART #0x8420 -> #0x8020

; Uart init

mov #0x8020, W0 ; W0 = 0x8020 -> 1000 0000 0010 0000b

mov W0, U2MODE ; Enable UART, AutoBaud and 8N1

clr U2STA

3. changing the start address 0xAE00 - 0x0100 = 0AD00

.equ CRC, W4

.equ ACK, 0x55

.equ NACK, 0xFF

.equ USER_ADDRESS, 0x0100

.equ START_ADDRESS, 0xAD00 ; Relative to 0x0100

4. using Internal FRC and PLL16

config __FOSC, CSW_FSCM_OFF & FRC_PLL16 ;Turn off clock switching and

;fail-safe clock monitoring and

;use the Internal Clock as the

;system clock

5. disabling MCLR (optional)

config __FBORPOR, PBOR_ON & BORV_27 & PWRT_16 & MCLR_DIS

;Set Brown-out Reset voltage and

;and set Power-up Timer to 16msecs

6. changing all the related registers of U1ART to U2ART, all U1XXX => U2XXX

U2MODE, U2STA, U2BRG, U2RXREG, U2TXREG

7. changing all the related registers of IC1 to IC2, all IC1XXX => IC2XXX

IC2CON, #IC2IF, #IC2IE

dsPicProgrammer (Java-based Multi-Platformed)

- Ingenia developed a programmer (PC-side) that works only in Windows environment. The project for Linux environment is currently suspended.

- A simple programmer (hereafter called dsPicProgrammer) written in Java based on the library developed by RXTX has been developed here. The programmer supports both Linux and Windows environments, and may be used as a substitution for the official programmer developed by ingenia.

- The programmer has the following specification and limitations:

- Use baud rate of 57600bps (Not selectable).

- Only program dsPic30f5011 devices (Developers may change the source code for your devices).

- Protection against overwriting bootloader codes on devices.

- Dectection if application program does not have its reset() at address 0x100.

Special Consideration

- The bootloader assumes that the user program starts at address 0x100. This is usually the case, but there are always exceptions.

- To ensure that the user program always starts at address 0x100, you can create a customized linker script and customized reset() function as follows:

- Copy and modify the file named "crt0.s" from the directory "C:\Program Files\Microchip\MPLAB C30\src\pic30" to the project directory and include it.

.section .bootloader, code //previously .section .libc, code

- Copy and modify the linkerscript for the device (e.g. p30f5011.gld) to the project directory and include it.

.text __CODE_BASE :

{

*(.reset); //<-insert this line here

*(.handle);

*(.libc) *(.libm) *(.libdsp); /* keep together in this order */

*(.lib*);

*(.text);

} >program

Downloads

| Program | Download | Remarks |

|---|---|---|

| dsPicBootloader | click here | Under "dsPicBootloader/", download ingenia.s and compile yourself |

| dsPicProgrammer | click here | Under "dsPicProgrammer/", dowload dsPicProgrammer.jar Alternatively, if you want to compile yourself or modify the source code, download COMDataHandler.java, COMPortManager.java, Pic5011Prog.java, Pic5011Protocol.java, and WriteBuffer.java under "dsPicProgrammer/" plus RdFileIntelHex.java under "IntelHexPaser/tags/0.02.00/". You should also install RXTX on your local machine as recommended in the readme file. |

Communication Protocol

- Communication Protocol is reviewed in ingenia bootloader user's guide section 2.1.3. The following summarises the key steps on the PC side (Refer also to section 2.2.2).

- Transmission is conducted in 8N1, i.e. 8-bit, no parity, 1 stop-bit

- Stage 1: User's configuation

- Select a baudrate

- Select a COM port channel

- Stage 2: Autobaud rate detection and version control

- Continuously sending a character "U" [0x55] via COM port

- Continuously waiting for an acknowledgment character "U", [ACK] = [0x55]

- Send command character [0x03]

- Receive 3 characters 1) Major Version 2) Minor Version 3) Acknowledgment [0x55]

- Prints the version number [Major.Minor] (e.g. 1.1) on screen.

- Stage 3: Loading and writing the program

- Load the user hex file, check integrity.

- Start loading file using:

- Read command character [0x01] + 24-bit address [High][Medium][Low]

- Receive 4-byte data [High][Medium][Low][ACK]

- Write command character [0x02] + 24-bit address [High][Medium][Low]+ Number of bytes [N] + [data 0] + [data 1] + ... + [data N-1] + [CRC]=(INTEL HEX8 Checksum - Sum modulo 256)

- Recieve [ACK] or [NACK] = [0xFF]

- Note: Writing is in row mode access (i.e. erase and write a whole row, each row has 32 instructions, or 96 bytes because each instruction has 24 bits)

- Ensure the initial address of writing match an initial row position,

- Send the data corresponding to the whole row.

USB-RS232 Bridge

- As USB ports are becoming more and more common, COM ports and Parallel ports may be redundant in the next few years. This section explore the possibilities of programming the target board through a USB port.

- There are two options:

- Use an external USB/RS232 adaptor, the driver will emulate a virtual COM port, such as Prolific and FDTI. Ingenia has tested its bootloader with some USB-232 manufacturers (silabs, FTDI, etc..). However, the programming failed with our Prolific adapter. Application program may use JavaComm API (javax.comm) and/or RXTX to drive the COM port.

- Modified the bootloader program on PC to support USB communication. e.g. using jUSB and JSR-80 (javax.usb). External circuits such as PIC18F4550 and MAX232 are required.

|--User's App.--|-------Device Manager------|-------USB-RS232 Interface------|---dsPIC---|

Option 1:

+-------------+ +----------+ +----------+ +---+ +------------+ +-----+ +--------+

| Application |--| JavaComm |--| Virtual |==|USB|--| FDTI |--|RS232|==| Target |

| Program | | RXTX | | COM Port | +---+ | Circuitary | +-----+ | Board |

+-------------+ +----------+ +----------+ +------------+ +--------+

Option 2:

+-------------+ +--------+ +---+ +------------+ +-----+ +--------+

| Application |----------| JSR-80 |==========|USB|--| PIC18F4550 |--|RS232|==| Target |

| Program | | jUSB | +---+ | MAX232 | +-----+ | Board |

+-------------+ +--------+ +------------+ +--------+

- Currently, when RXTX is incorporated with JavaComm API, operating systems supported include Linux, Windows, Mac OS, Solaris and other operating systems. On the other hand, jUSB and JSR-80 only works for linux.

FDTI Chipset

- FT232RL communicateS with PC via USB to provide 1 UART channel.

- Datasheet can be downloaded here.

- Refer to Fig. 11 (Page 19) for Bus Powered Configuration.

- Refer to Fig. 16 (Page 24) for for UART TTL-level Receive [RXD -> 1], Transmit [TXD -> 4], Transmit Enable [CBUS2/TXDEN -> 3]. Omit Receive Enable [CBUS3/PWREN#] and use [CBUS2/TXDEN -> 2]

- Refer to Fig. 15 (Page 23) for LED Configuration: [CBUS0/TXLED#] and [CBUS1/RXLED#]

- Virtual COM Port Drivers can be downloaded here.

Programming the Device

Requirements

- Hardware

- PC with COM port (Windows XP Installed for MPLAB)

- ICD2 Programmer

- Target Board

- 5V Power Supply

- Software

- MPLAB IDE v7.50 or higher

- dsPicProgrammer (dsPicProgrammer.jar)

- RXTX driver

- Files

- dsPicBootloader (ingenia.hex). Original assembly code by ingenia can be downloaded from here.

- Application hex file (e.g. app.hex)

Loading Bootloader (Once only)

| Step | Remarks |

|---|---|

| Install MPLAB IDE |

|

| Install USB Driver |

|

| Select Target Chip |

|

| Target <-> ICD 2 |

|

| ICD 2 <-> PC |

|

| Load Bootloader |

|

| Start Programming |

|

| Finishing |

|

Loading Application

| Step | Remarks |

|---|---|

| Install RXTX |

|

| Connect target board |

|

| Open a console window |

|

| Start Programming |

|

| Finishing |

|

FreeRTOS and POSIX-compliant API

- FreeRTOS is a free real-time operating system for many embedded systems.

- FreeRTOS provides basic tools to distribute processing time to tasks (scheduling) and manage memory queues.

- FreeRTOS does not provide an API to handle system resources, e.g. uart, eeprom (i.e. files). Users have to implement these functions themselves to allocate this resources to differnt tasks.

- A POSIX-compliant API for file access is used in this applicantion.

POSIX-compliant API

- POSIX (Portable Operating System Interface for uniX) is a IEEE standard API for Unix OS.

File Descriptor

- File descriptors range from 0 through OPEN_MAX defined in <limits.h>

- By convention the Unix shells associate file descriptor 0 with the standard input of a process, file descriptor 1 with the standard output, and file descriptor 2 with the standard error. These are defined by the symbolic constants STDIN_FILENO, STDOUT_FILENO, and STDERR_FILENO in <unistd.h>

Remote Access

- At the moment, local devices (e.g. EEPROM, ADC, DAC, etc.) can only be accessed locally through POSIX functions such as open(), read(), write(), ioctl().

- However, a client may need to access these devices on a remote server. This section reviews the background and gives some ideas on its possible implementation.

Requirements

- A remote file access protocol, to transfer "files" (i.e. device's data) such as:

- File Transfer Protocol (FTP): Required files are copied from sever to client for manipulation

- Remote Shell (RSH): Required files are copied from sever to client for manipulation

- Network File System (NFS): Required files are manipulated on sever

- An API to access files using a selected protocol, such as:

- lam_rfposix: A POSIX-like remote file service for Local Area Multicomputer

- API employed by VxWorks: VxWorks is a Unix-like real-time operating system, commonly used for embedded systems.

API Reference for VxWorks

- Reference:

- Related Libraies

- netDrv (netDrv.h): an API using FTP or RSH

- nfsDrv (nfsDrv.h): an API using NFS

To Do List

- Explore the possibilities of using USB/RS232 interface

- Review on standard means to access remote and local devices

- Incorporate Free RTOS

- Construct examples codes for using DSP library

- Construct examples codes for using Build-in library

- GUI Interface for Benchtop boards