Difference between revisions of "Techniques"

(mention conformal coating) |

|||

| Line 150: | Line 150: | ||

(Have you seen this [http://hackaday.com/2007/06/04/cnc-solder-pastepick-n-place/ CNC solder paste/pick n place] ?) | (Have you seen this [http://hackaday.com/2007/06/04/cnc-solder-pastepick-n-place/ CNC solder paste/pick n place] ?) | ||

''Hackaday has lots of other similar articles: [http://hackaday.com/?s=solder+paste search hackaday for "solder paste"]'' | ''Hackaday has lots of other similar articles: [http://hackaday.com/?s=solder+paste search hackaday for "solder paste"]'' | ||

| + | |||

| + | (Optional: ) After all the parts are completely soldered down, some people like to spray the board with some kind of conformal coating, or completely seal in the board with some kind of potting compound. | ||

| + | See [http://electronics.stackexchange.com/questions/5095/whats-the-best-way-to-protect-a-board-from-corrosion-in-a-hot-moist-environment "Electronics and Robotics: What's the best way to protect a board from corrosion in a hot/moist environment?"]. | ||

== [[Hardware tool]]s == | == [[Hardware tool]]s == | ||

Revision as of 10:22, 7 February 2011

There are a wide variety of techniques used in electronics.

Contents

- 1 Printed circuit board design/fabrication

- 2 Best Practices for PCB Layout

- 3 Circuit construction (Prototyping - Other than custom PCB)

- 4 Soldering techniques

- 5 Hardware tools

- 6 software tools

- 7 Software design tools

- 8 PC-Microcontroller Communications

- 9 Embedded System Programming and Testing

- 10 driving motors

- 11 Enclosure

- 12 Misc Tips Tricks

- 13 Further Reading

- 14 Environmental Issues

Printed circuit board design/fabrication

Overview

Software Design

See Software Design Tools below.

Step by Step by using Software Design Tool

- make sure the dimension and shape of PCB

- make sure the size and location of Via for PCB stand

- Make sure each components footprint.

- each components are placed on suitable place by put on a hardcopy of simulation PCB

- All components get enough clearance between them.

- Silkscreen layout is confirmed.

- PCB is drawn.

- silkscreen adding the following:

- version no.

- organization name

- board name

- Netlist is ran and got a no error result.

- DRC is ran and got a no error result.

- Overall is checked.

- generate Gerber and send to PCB Manufacturers.

Manual Design

Somepeople do this with layout on clear film or by directly drawing on a circuit board, of even by scratching, grinding.... For now let them google this.

Homebrew fabrication

Before exploring these techniques, you should understand your options with regard to services such as BatchPCB.com, ExpressPCB.com and PCB123.com. Being able to have several boards fabbed in 2 days for $59 (for example) makes it harder to justify the hassle of etching your own boards at home.

- "How to make really really good homemade PCBs" by Mike Harrison 2007

- "Etching PCBs using Toner Transfer" and "Milling PCBs" by Francis Esmonde-White, includes information on how to go from Eagle PCB to the etching or milling step

- Toner Transfer -- This method involves laser printing your PCB design onto paper, then transferring toner onto copper-clad board.

- Photoetching -- Exposure of PCB designs onto photosensitized copper-clad board.

- Chemical Etchants

- "Mechanically etching or milling PCBs. No chemicals!" -- Use your CNC router/mill to make PC boards.

- Open Source Ecology wiki: "Routed Circuit Board"

- Yahoo group: Homebrew_PCBs · Homebrew Printed Circuit Boards

- RepRap wiki has details on how to use open-source RepRap-based desktop routers to cut PCBs out of copper-clad board.

- "pcbprt - Experiments in inkjet PCB printing" by pascal. Some inkjet printers can print directly CD and DVD. Pascal explains step-by-step how to get those printers to print on copper-clad FR4 to make reasonably good etch resist. The main trick seems to be baking the freshly-printed boards to dry out the ink and get the dyes/pigments to stick to the copper -- otherwise the water-based ink immediately washes off as soon as you drop the board in the etch tank.

- A few people have made "DIY Flex Circuits".[1]

Commercial PCB fabrication

- Submitting PCB's for fabrication -- Common processes for submitting PCB's for fabrication.

- PCB Manufacturers

- "PCB fabbing advice" by Chris Anderson 2008

Best Practices for PCB Layout

Theory

- Provide the easiest path (lowest impedance) for current to flow

- Return current tends to flow directly under signal trace (for PCB having ground plane)

- Inductance increases with length of traces

- Inductance increases with the area enclosed by signal trace and ground

- Prevent digital currents from contaminating analog currents

- Decouple high speed components

- Use ground loop avoidance tehniques

Design

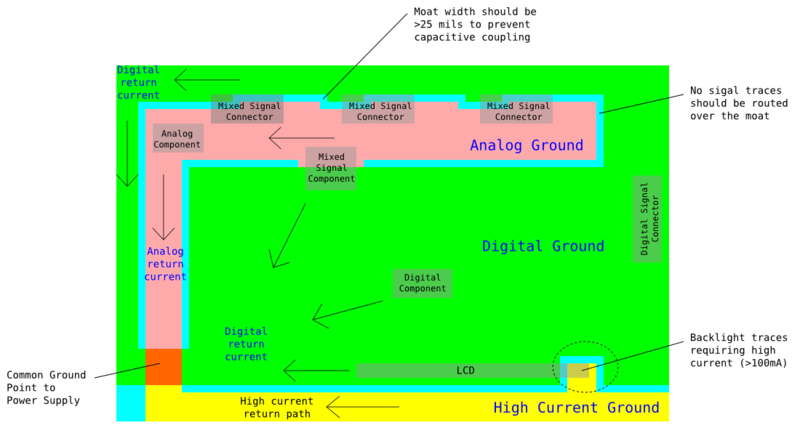

- Partition PCB into "analog stuff" and "digital stuff".

- No digital signal traces should cross over analog ground, and vice versa

- For components having both analog and digital signals (e.g. ADC), orientate components so that the analog signal traces goes only over the analog ground plane, and digital signal traces goes only over the digital ground plane

- AGND and DGND of ADC must have a small impedance (i.e. separated by short distance)

- Add decoupling capacitors close to Vcc and DGND of ICs

- Add ferrite beads and capacitors (PI-filter) to power rail for low-pass filtering (reduce ripples).

Routing

- Place fixed components first (components location that cannot be changed, e.g. connectors, buttons, etc)

- Make installing parts onto the PCB fast:

- Fastest: No through-hole parts. All surface-mount parts on the bottom side.

- Next-fastest: All through-hole parts on the top side. All surface-mount parts on the bottom side. ( "Mighty Mouse Main Printed Circuit Board (PCB)" )

- Separate components into groups

- Digital signals only

- Analog signals only

- Digital and analog (Mixed) signals

- High current devices (e.g. led backlight for LCD/buzzer)

- Do not partition ground into analog and digital planes.

- Use a single ground plane. See the " Grounding References" below.

- Orientate components that have mixed signals according to the orientation of the ground planes, and straddle components over DGND and AGND

- Place digital only components over DGND

- Place analog only components over AGND

- Decoupling capacitors should be as close to the ICs as possible

Vcc

| | | | |

+-----------+

-------+-+--|-+---------|-------- Vcc

|C| | IC |

-------+-+--|---------+-|-------- GND

+-----------+

| | | | |

GND

- Lay critical (noise-sensitive) traces first (e.g. crystal, analog signals)

- As short as possible

- Use 45o turnings instead of 90o

- Paired signal traces (e.g. TX+, TX- in ethernet chips) should run parallel along each other

TX+ -----\

TX- ----\ \

\ \

\ \

\ \

\ \------------ TX+

\------------- TX-

References

- Grounding

- Partitioning and Layout of a Mixed Signal PCB: The importance of single ground plane and partitioning of analog and digital signal trace

- Massmind Techref: "Unsplit ground"

- Ground- A Path For Current Flow: The importance of decoupling capacitors

- PCB Layout Tips: a power point presentation

- PCB Layout Guidelines: in Traditional Chinese

- Crystals and Oscillators

- AVR186: Best Practices for the PCB layout of Oscillators

- ADC & Analog Filters

- ADN007: Techniques that Reduce System Noise in ADC Circuits

- ADN010: Predict the Repeatability of your ADC to the BIT

- AD699: Anti-Aliasing, Analog Filters for Data Acquisition Systems

- AN682: Using Single Supply Operational Amplifiers in Embedded Systems

- AN990: Analog Sensor Conditioning Circuits - An Overview

- EMC

- AVR040: EMC Design Considerations

- AN1705: Noise Reduction Techniques for Microcontroller-Based Systems

- AN898: EMC general information

- AN901: EMC guidelines for microcontroller-based applications

- AN1709: EMC design guide for ST microcontrollers

Circuit construction (Prototyping - Other than custom PCB)

- Solderless protoboard (Wikipedia:Breadboard) (a simple example with a small microcontroller)

- Point-to-point (Wikipedia:Point-to-point construction)

- Wirewrap (Wikipedia:Wire Wrap)

- Dead bug style

- Manhattan style aka "A Modern Breadboarding Technology: Insulating Pads Soldered to a Ground Plane"

- "Ugly Construction" (like deadbug... )

"Construction Ideas" has nice photographs of the above circuit construction techniques. ["Effects Building Techniques" by R.G. Keen 1999 reviews, compares, and contrasts these techniques for circuit construction -- also a few more.

- Stripboard (Veroboard): (Wikipedia:stripboard.)

Soldering techniques

- Basic soldering -- How to use a soldering iron.

- Surface Mount

- Skillet reflow

- Toaster oven reflow

- Hot air soldering

- A few different SMT assembly methods that you can do at home on a cheap budget

- Rework -- Techniques for fixing mistakes, or for adding new features to a board that almost does what you want.

(Have you seen this CNC solder paste/pick n place ?) Hackaday has lots of other similar articles: search hackaday for "solder paste"

(Optional: ) After all the parts are completely soldered down, some people like to spray the board with some kind of conformal coating, or completely seal in the board with some kind of potting compound. See "Electronics and Robotics: What's the best way to protect a board from corrosion in a hot/moist environment?".

Hardware tools

A directory of hardware tools that you may find useful.

software tools

Software design tools

A directory of software tools that you may find useful.

PC-Microcontroller Communications

Discussion of the various methods to connect a microcontroller or embedded system to a PC...

Embedded System Programming and Testing

To add to the confusion programming in embedded system can mean a person writing a program or a device called a programmer "burning" a program into a chip. This section is for the "burning" meaning of programming.

- Many systems use JTAG for programming and testing. (Such as Atmel AVR embedded systems]).

- Other systems use some other kind of in-circuit programming.

- Some people use bootloaders to make re-programming a little quicker.

-- not sure that this next one is not misplaced ? -- We're talking about "programming and testing" ? What else do you use to test op-amp circuits?

- Many people use an oscilloscope (o'scope). See oscilloscope for a list of Keith has made a list of low-cost o'scopesl "PC USB logic analyzers that cost under $1000." for a list of low-cost logic analyzers.

Humans writing a program almost always do it in a language. Here is a section that discusses some of these languages: Programming Languages

driving motors

See Stepper Motor Tester and motor driver.

Enclosure

- The Earth Signal should short to whole metal Case

- Digital/Analog GND should separate to this Earth Signal, and should connect a Y-cap. to filter the noise between them.

- Attention: do not place near between Earth Signal and Digital/Analog GND, otherwise some spark come out, and affect your whole system.

- See enclosures.

Misc Tips Tricks

Further Reading

- "Electronics Design" from Airborn gives an overview of the complete process: specification, (schematic) circuit design, layout, prototypes, firmware, pilot run, production.

- EDA electronic design automation software is a subset of CAD in general. Is there a wiki that discusses CAD in general? Until I find it, I'm going to post these tools here: "Google SketchUp is a powerful yet easy-to-learn 3D software tool" http://sketchup.google.com/ ; "Inkscape is the best tool for SVG standard vector graphics" http://wiki.inkscape.org/ ; Visual Wiki http://visualwiki.org/

- "What's All This Ground Noise Stuff, Anyhow?" by Robert A. Pease

- "What's All This Teflon Stuff, Anyhow?" by Robert A. Pease -- explains a situation using lots of metal (instead of carefully insulating everything with lots of Teflon) causes less noise. Also mentions "why am I telling you all of these details? If I design a tester with greatly improved performance to help me test a really high-performance product, why should I tell all our competitors so that anybody in the world can test their products using the improved tester? Why should I give away all of these hard-earned secrets?" and gives some very good reasons.

- sci.electronics.design: EDN: Measuring Nanoamperes discusses some ways to measure extremely small currents.

- MillPCBs.com for techniques on using a small cnc machine to mill PCB's

- yahoo.com/group/Homebrew_PCBs

- electricstuff.co.uk/pcbs

- fullnet.com/~tomg/gooteepc

- Dave McGuire says "The notion that through-hole soldering is easier than soldering surface-mount devices is, and always has been, a myth." (Now, about keeping all the look-alike passive parts straight... :) )

- Intro into SMD Soldering

- PMinMO.com is THE PLACE for DIY CNC driver information

- 18 Essential Skills for a Maker